In today’s rapidly developing world, heavy machinery noise has become a serious challenge for surrounding communities. Construction sites, manufacturing plants, and industrial operations depend on machines—but the constant roar creates noise pollution that can harm health, lower productivity, and spark community complaints. Managing this impact is crucial for compliance and sustainability.

Understanding Noise Pollution

Noise pollution is more than just an annoyance. Prolonged exposure to heavy machinery noise can cause:

- Hearing loss

- Sleep disturbances

- Increased stress and anxiety

- Reduced productivity

- Negative impacts on wildlife

With these concerns in mind, it’s crucial to implement noise reduction strategies for heavy machinery operations.

Proven Results with Equipment Shrouds

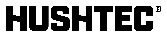

One of the most effective ways to reduce heavy machinery noise is through equipment shrouds—specialized covers that absorb and block sound waves..

Equipment Shrouds: Reducing Heavy Machine Noise Effectively

How Equipment Shrouds Reduce Heavy Machinery Noise

- Absorbing sound waves

- Deflecting noise away from surrounding areas

- Creating a barrier between the noise source and the environment

Effectiveness of Shrouds for Heavy Machinery Noise

- Reduce noise by 20–30 dB

- Improve compliance in noise-sensitive zone

Hushtec Noise Control Shrouds

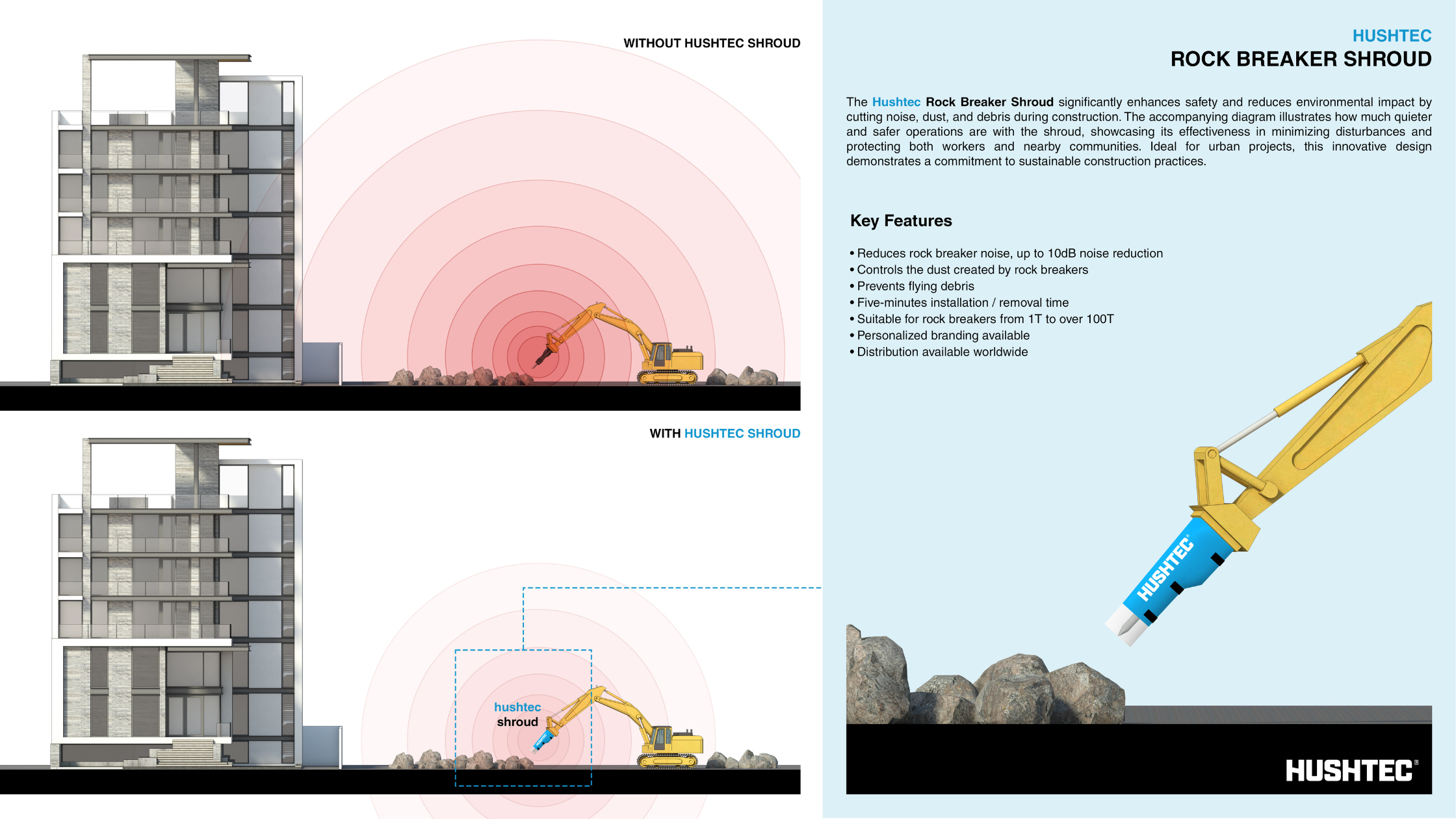

Hushtec provides innovative, durable solutions tailored for noisy construction equipment:

- Pile Driver Shroud – Reduces high-impact noise during piling, ensuring safer and compliant worksites.

- Rock Breaker Shroud – Minimizes extreme sound from rock-breaking tasks without compromising performance.

These products demonstrate how modern engineering tackles machinery noise, balancing productivity with community well-being.

By integrating innovative shroud solutions like those from Hushtec, industries can address noise concerns more effectively, ensuring a quieter, more sustainable work environment.

Additional Noise Control Solutions

Beyond shrouds, industries can combine strategies for maximum impact:

- Sound Barriers – Acoustic panels, fences, or even natural barriers like trees.

- Regular Maintenance – Lubrication, part replacement, and tightening reduce rattles and vibration noise.

- Quieter Machinery Models – Switching to electric or hybrid equipment lowers sound levels.

- Scheduling Operations – Plan noisy activities during acceptable hours in coordination with local communities.

Conclusion

Addressing heavy machinery noise is not just a matter of regulatory compliance; it’s a crucial step towards creating more livable and sustainable environments. By implementing strategies like equipment shrouds, sound barriers, and thoughtful operational planning, industries can significantly reduce their noise footprint.

As we continue to progress and develop our urban and industrial landscapes, it’s essential to balance productivity with the well-being of surrounding communities. Through innovative solutions and a commitment to noise reduction, we can ensure that the sounds of progress don’t come at the cost of our quality of life.