Temporary acoustic barriers are increasingly recognized as an indispensable tool for responsible builders. In today’s fast-paced construction industry, managing noise pollution has become a critical part of project management. These barriers not only support compliance but also help protect communities, improve worker safety, and maintain positive public relations. This article explores their importance and best practices for effective installation on construction sites.

The Necessity of Noise Control in Construction

Construction sites are inherently noisy environments, with various activities contributing to sound pollution:

- Heavy machinery operation

- Demolition processes

- Power tools and equipment

- Vehicle movements

Effective noise control is crucial for:

- Compliance with local regulations

- Maintaining good relationships with neighboring communities

- Protecting workers’ hearing health

- Enhancing overall project efficiency

Explore more of our Hushtec noise control solutions designed to meet the unique challenges of construction and industrial projects.

1. Durability and Weather Resistance

Construction-site barriers must withstand:

- Harsh weather conditions

- Frequent relocations

- Potential impacts from equipment

2. Modularity and Flexibility

Effective barriers offer:

- Easy assembly and disassembly

- Adaptability to various site configurations

- Scalability for projects of different sizes

3. High Noise Reduction Capability

Quality barriers typically provide:

- Significant decibel reduction (often 15-30 dB)

- Absorption of a wide range of frequencies

For site-specific challenges, acoustic barriers for construction provide tailored solutions that balance performance and flexibility.

Best Practices for Installation on Construction Sites

1. Strategic Placement

- Surround the perimeter of noisy work areas

- Create enclosed spaces for particularly loud equipment

- Position barriers between noise sources and sensitive receptors (e.g., residential areas)

2. Proper Height and Coverage

- Ensure barriers extend well above the noise source

- Overlap panels to eliminate sound leaks

- Consider double-layer installations for enhanced performance

3. Secure Mounting

- Use sturdy temporary fencing or scaffolding as support structures

- Employ robust fastening systems to withstand wind loads

- Regularly inspect and maintain barrier integrity

4. Integration with Site Layout

- Incorporate acoustic barriers into the site planning phase

- Coordinate barrier placement with traffic flow and material storage areas

- Adjust barrier configurations as the project progresses

Additional Noise Mitigation Strategies

1. Equipment Selection and Maintenance

- Choose modern, quieter equipment when possible

- Maintain machinery regularly to prevent excess noise from worn parts

2. Work Scheduling

- Plan noisiest activities during less sensitive hours

- Rotate noisy operations to distribute impact

3. Worker Training

- Educate staff on the importance of noise control

- Train teams in proper use and maintenance of acoustic barriers

Complementary measures may also include using industrial soundproofing products that extend beyond barriers to treat machinery and internal structures.

Benefits of Implementing Acoustic Barriers

- Regulatory Compliance: Meet or exceed local noise ordinances

- Community Relations: Demonstrate consideration for neighboring residents and businesses

- Worker Well-being: Reduce noise-related stress and potential hearing damage

- Project Efficiency: Minimize complaints and potential work stoppages due to noise issues

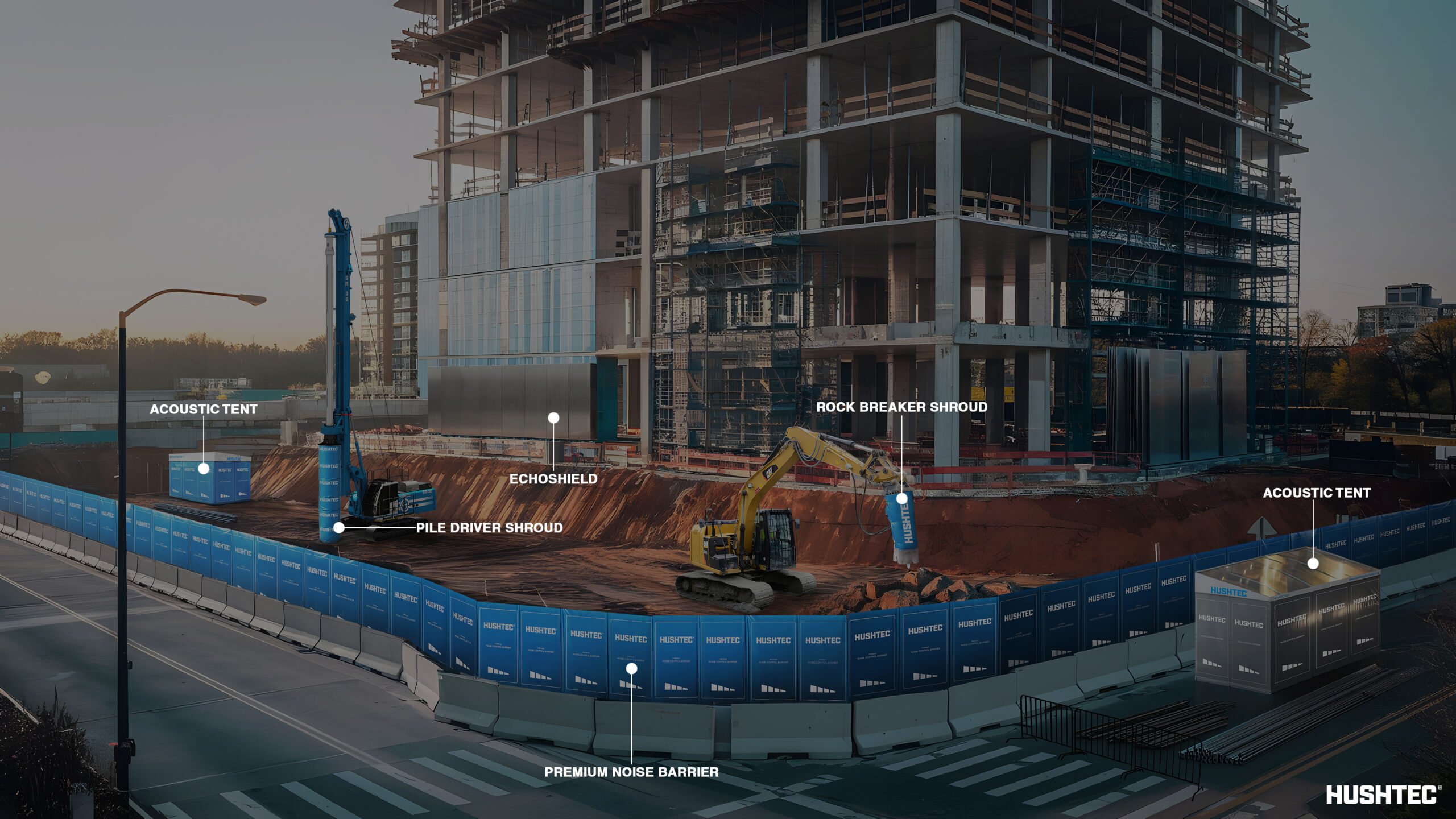

Proven Noise Control Solutions – Hushtec

Hushtec offers a range of innovative noise control solutions designed specifically for construction sites and other noisy environments. The Premium Noise Barrier is a highly effective and versatile option for managing construction noise.

Key features of Hushtec’s Premium Noise Barrier include:

- Exceptional noise reduction: Up to 43dB noise reduction capability

- Customization: Fully customizable in size, shape, and color to meet specific project requirements

- Durability: Weatherproof construction for both indoor and outdoor use

- Easy installation: Velcro connections for minimal noise leakage and tensioned eyelets for secure mounting

- Portability: Standard size of 2m tall x 1.3m wide, ideal for temporary fencing and scaffolding

Temporary acoustic barriers are more than just a regulatory requirement; they’re a cornerstone of responsible construction practices. By implementing these barriers effectively, construction companies can significantly reduce their environmental impact, protect their workforce, and maintain positive community relations.

As the construction industry continues to evolve, the integration of noise control measures like acoustic barriers will play an increasingly vital role in sustainable and community-friendly development. Learn more about the industries we serve or contact Hushtec for tailored project solutions.