Construction Sites Have Changed — Traditional Timber Hoardings Haven’t – this is the reality. Construction sites today operate in environments that are more constrained, more visible, and more regulated than ever before. Projects increasingly sit alongside occupied buildings, active public spaces, and critical infrastructure — leaving little margin for disruption.

At the same time, expectations around construction site noise control, environmental performance, and professional presentation have risen sharply. Site boundaries are no longer just physical barriers; they play an active role in managing sound, communicating with stakeholders, and protecting surrounding environments.

Despite these changes, many projects still rely on plywood and timber hoardings — materials that were never designed to address modern noise management or sustainability requirements.

This disconnect has led to a growing shift toward acoustic construction barriers engineered specifically for contemporary construction challenges. Among these, Hushtec acoustic barrier systems are emerging as a clear alternative to traditional timber hoardings.

Effective construction site containment is critical for reducing noise, protecting surrounding communities, and meeting regulatory requirements. This comparison explores Hushtec acoustic barriers versus traditional timber hoardings, highlighting performance, compliance, safety, and long-term cost efficiency across modern construction environments.

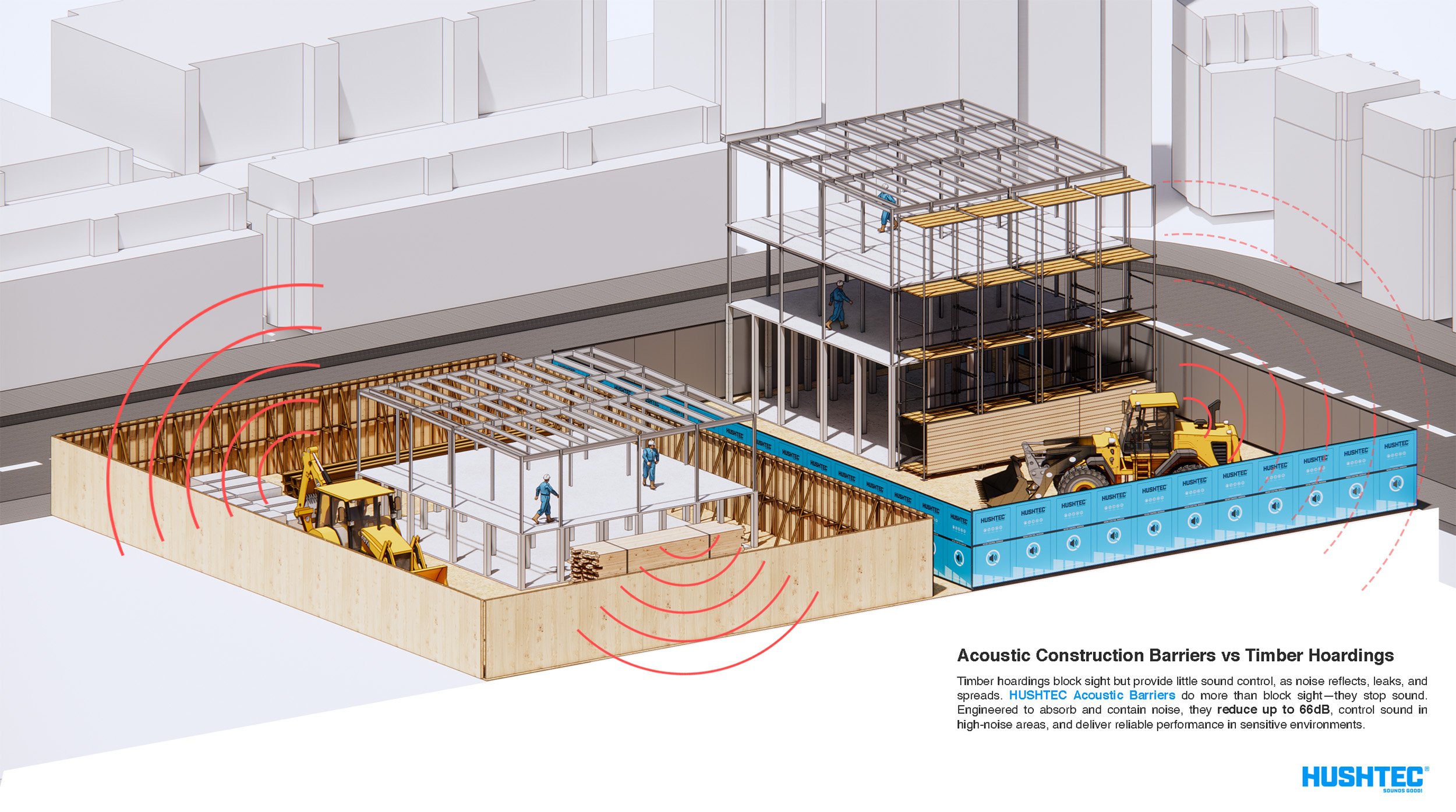

Acoustic Construction Barriers vs Timber Hoardings

Plywood hoardings provide basic visual screening but offer minimal acoustic performance. Sound reflects off hard timber surfaces, escapes through gaps between panels, and travels easily around rigid structures.

Hushtec barriers function differently. They are purpose-built acoustic barrier systems designed to absorb and contain sound energy rather than simply block sightlines. This results in:

- Up to 66dB noise reduction

- Controlled sound absorption across high-noise activities

- Reliable performance in noise-sensitive environments

For projects where noise impact directly affects compliance, productivity, or community relations, this difference is critical.

Noise Reduction Performance on Construction Sites

Effective construction noise management requires more than physical separation. It requires materials and systems engineered to address how sound behaves in real-world conditions.

Hushtec acoustic barriers deliver measurable noise reduction by combining:

- Absorptive materials that limit sound reflection

- Continuous barrier design that reduces leakage

- System-level performance rather than individual panel effectiveness

Compared to timber hoardings, which vary widely in quality and installation, Hushtec provides predictable, repeatable results.

Outcome:

- Reduced off-site noise transmission

- Improved compliance with noise limits

- Fewer complaints and interruptions

Why Modular Acoustic Barriers Outperform Rigid Hoardings

One of the most significant limitations of plywood hoardings is poor modularity. Panels are heavy, difficult to align, and prone to gaps — each one acting as an acoustic weak point.

Hushtec panels are designed as modular acoustic barriers, featuring:

- Lightweight, easy-to-handle panels

- Flexible configurations for changing site layouts

- Industrial Velcro seams that create continuous acoustic seals

This modular approach ensures performance consistency while allowing rapid reconfiguration as projects evolve.

Outcome:

- Fewer noise leaks

- Faster installation and adjustment

- Cleaner, more professional site boundaries

Branded Construction Barriers and Site Presentation

Construction sites are highly visible, particularly in urban and mixed-use environments. Traditional timber hoardings offer little opportunity for visual control or communication.

Hushtec barriers can be custom printed, allowing site boundaries to incorporate:

- Company branding and logos

- Project information

- Safety messaging or wayfinding

This transforms barriers from temporary obstructions into structured, professional communication assets.

Outcome:

- Stronger brand presence

- Clearer public messaging

- Improved stakeholder perception

Sustainability and Reusability in Construction Barriers

Plywood hoardings are often treated as short-term materials — installed, damaged, and discarded after a single project. This approach generates waste and increases long-term costs.

Hushtec barriers are designed as reusable construction site barriers, offering:

- Durable, weather-resistant construction

- Reuse across multiple projects

- Materials that support recycling at end of life

By shifting from disposable materials to reusable systems, projects can significantly reduce waste and improve lifecycle performance.

Outcome:

- Lower environmental impact

- Reduced material consumption

- Better return on investment over time

Installation Efficiency and Labour Cost Reduction

Installing timber hoardings typically requires framing, fixings, power tools, and skilled labour — all of which add time and cost.

Hushtec acoustic barriers are engineered for rapid deployment:

- No power tools required

- No specialist trades needed

- Lightweight panels for safe manual handling

- Fast installation and pack-down

This makes them particularly effective for temporary works, fast-moving projects, and sites with changing layouts.

Outcome:

- Reduced labour costs

- Faster site setup and removal

- Increased operational flexibility

Comparing Hushtec Barriers and Timber Hoardings

| Feature | Plywood & Timber Hoardings | Hushtec Barriers |

| Acoustic Performance | Minimal | Up to 66dB reduction |

| Installation | Labour and tools required | Tool-free installation |

| Modularity | Limited | Fully modular system |

| Branding | Limited | Custom printed |

| Sustainability | Short lifespan | Recyclable and reusable |

| Site Finish | Basic | Professional |

The Future of Construction Site Noise Management

As construction environments become more complex and regulated, reliance on legacy containment methods introduces unnecessary risk and inefficiency.

Acoustic barrier systems like Hushtec represent a shift toward engineered, system-based solutions — combining measurable noise reduction, operational efficiency, sustainability, and professional site presentation.

For projects where performance, compliance, and perception matter, moving beyond timber hoardings is no longer an upgrade — it’s a necessity.

Ready to Upgrade Your Construction Site Containment?

If your project demands effective construction site noise control, faster installation, and a more sustainable approach, Hushtec acoustic barriers provide a proven alternative to plywood hoardings.